Joanne

4/14/2025 10:20:21 AM

4 mins read

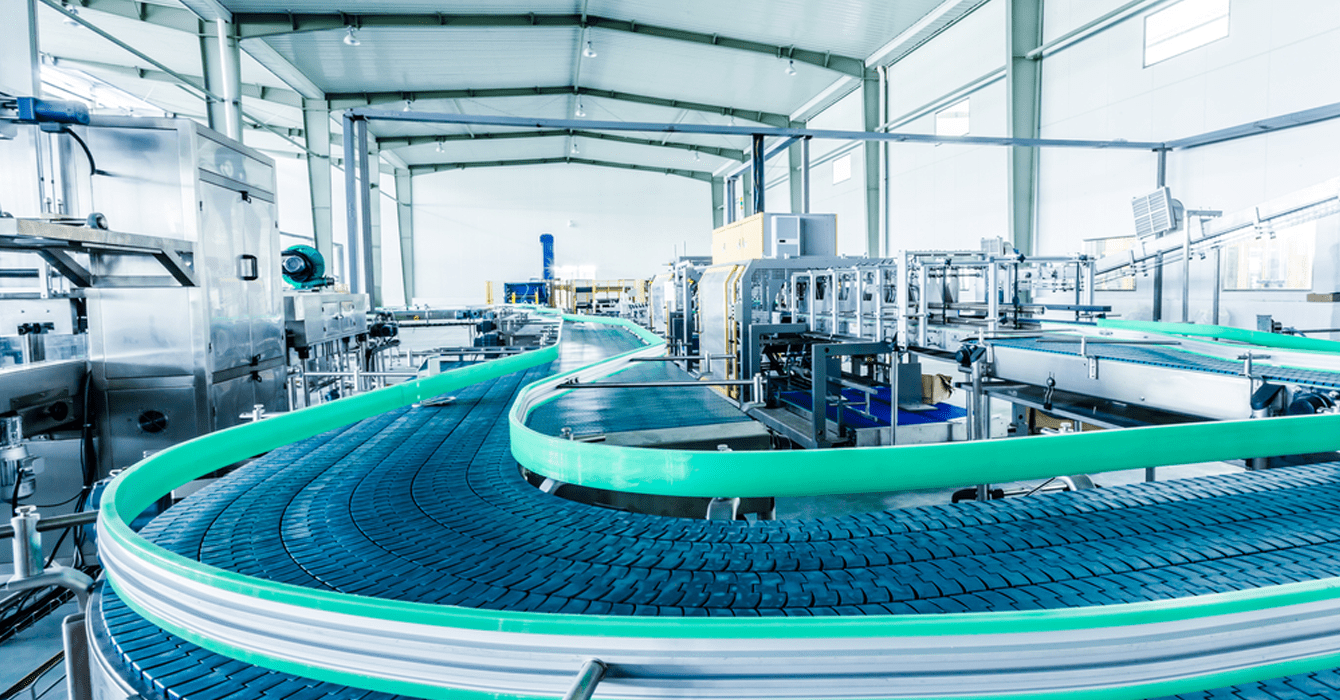

You face many challenges to your ability to compete in the food processing industry. With the expectation of doing more with less now an ever-present priority, finding savings is an essential part of any successful production strategy.

Gaining Back Precious Time

Time is the golden parameter. Rapid turnaround is crucial in the food processing sector.

With soaring utility and labour costs – with labour typically up to 65% of Open Plant Cleaning (OPC) costs - any reduction in the length of the cleaning process has a significant direct impact.

Saving time can give you a competitive edge, enabling you to free up your workforce and unlock more valuable production capacity. While saving resources contributes to achieving your sustainability goals and in satisfying changing consumer attitudes.

You Need the Right Expertise to Innovate

You cannot hope to respond successfully to external challenges if your cleaning processes are not running at peak performance. Consistent hygiene standards are the foundation of all safe and successful food production. Food safety compromised by microbial contaminants threatens consumer health and can have serious long-term impact for your brand equity.

World class sector-specific knowledge and experience is key to identifying where savings can be implemented, and in developing the innovations that can achieve these aims safely and efficiently. Diversey’s expertise across all aspects of food production means you can trust that our solutions drive sustainability and add value, yet maintain compliance to the highest standards of hygiene and food safety.

Reduce Your Cleaning Window By Targeting Each End of Your Process

Cleaning procedures have always incorporated rinse steps. Pre-rinse, between steps, and a final residue removal rinse before production commences. It’s all a familiar necessity. However, what if you could limit the time necessary for your pre-rinse, and remove your final rinse altogether?

Diversey has innovations that can now target your cleaning process at the initial and final rinse stages. DiverClean Sonic and Divosan Dew offer you two transformational technologies that push back the boundaries of required cleaning time, but without sacrificing food safety - or by creating any trade-off with hygiene standards.

DiverClean Sonic Transforms Your Pre-Cleaning Step

DiverClean Sonic is a pre-cleaning step technology - comprising an alkaline foaming agent – that removes all soil ready for a light rinse and disinfection. It challenges decades of traditional cleaning practice and transforms your OPC by reducing the need for time consuming pre-rinsing.

You can significantly reduce overall cleaning time and labour requirements, along with downtime, and achieve impressive resource savings that provide appreciable water, chemical and energy - compressed air and temperature – savings. You gain additional production time and contribute to your crucial sustainability targets, without impacting on cleaning performance or food safety.

DiverClean Sonic unlocks savings for you in four key areas:

Time (Cleaning) – Up to 35% savings

Water and Wastewater – Up to 20% savings in each

Energy – Up to 20% savings

Chemicals - Up to 20% savings

In current market conditions, releasing available production time and capacity is essential in contributing toward your business resilience and competitiveness.

Less Cleaning Time Means Using Less Resources

The impact upon processors has been transformational. A red meat processing plant in the Netherlands reduced the cleaning process by the equivalent of 11 man hours, delivering significant water and energy savings, while also improving the working environment for their employees.

Choosing the Right Innovations Can Help You Stay Ahead of the Game

In any drive to remain competitive, it’s crucial to avoid sacrificing your food safety to the pressures to achieve more efficiency, sustainability, and productivity. If you jeopardize hygiene standards in the pursuit of resource savings and production time, it can easily lead to lower quality products, consumer dissatisfaction, and product recall. There are times this can feel like an impossible challenge. After all, your hygiene program is already designed to meet/exceed regulatory standards necessary to ensure food safety.

However, with water scarcity, climate change, and new product expectations, the requirements of retailers, consumers, and regulatory bodies are changing, driving demands for even higher standards. Also, you now have to work with the understanding that this must also be done with safer chemistry, lower use of resources, and in less time.

Divosan Dew helps you to meet these expectations by targeting your final rinse. Its innovative technology can help save you time, reduce your water usage, and meet production demands.

No Rinse, No Residues

Divosan Dew’s formulation from natural compounds offers a better way. There’s no need for a final rinse, and no risk of chemical residues associated with traditional biocides based on Quaternary Ammonium Compounds, Hypochlorite, or Akylamines.

With water savings now a priority for any responsible producer, Divosan Dew’s rinse-free application and streamlined process naturally saves water and time, with benefits from reduced wastewater, and less chemical components adding to your water treatment bill.

Overcome Any Reluctance and Make Significant Savings

Your cleaning cycle cuts into available production time with significant cost, especially if you have capacity constraints. DiverClean Sonic and Divosan Dew release time back from your cleaning schedule and turn it into profitable production capacity.

You can’t afford to be reluctant in changing your traditional cleaning processes, otherwise you’re not only limiting your potential to meet these demands, you can be left behind through reliance on outdated practices. It’s convenient to lapse into the attitude that - “this is the way we’ve always done it.”

One of Diversey’s partners – a European-based Protein processor - is enjoying the benefits of choosing innovation and Divosan Dew’s reliable and substantial savings, with:

Up to 20% time saving – equivalent of 27 hours per week.

Up to 20% water saving – resulting in 48,000 litres per week.

Up to 20% wastewater saving – totalling 48,000 litres per week.

Adopting Innovation with Control and Confidence

Our consultation-based approach ensures that adopting our innovations is a controlled and thorough process leading to these benefits, and the peace of mind knowing you have the best current process tailored for your specific circumstances.

Together, DiverClean Sonic and Divosan Dew can deliver time savings from your cleaning process of up to 50%.

By partnering with Diversey’s extensive experience, application support - and our determination to deliver the optimum hygiene results and reduce your sustainable footprint - you and your process are in the safest hands.

By applying the transformational combination of DiverClean Sonic and Divosan Dew, you can reduce your consumption of resources and time. You can be confident of meeting changing production demands and face future challenges from a position of strength - all without risking your crucial food safety standards and your reputation.